After a couple of days off to ride coasters at Cedar Point (yes, with a concussion!) and visit Wellzy… I’m back home and back to work.

Today’s task: More engine diagnosis. Pull remnants of bumper and put car in service mode so I can further inspect engine and sensors. Do compression and leak down tests (using new tools that arrived yesterday). If OK, let it run a bit to burn oil out of cylinders, see how it runs, and let the bearings work a bit. Pull oil sample to test for bearing damage.

First, took an opportunity to look at my left GP skirt which got removed WITH MALICE by the ditch. Sadly, it sheared off EVERY SINGLE MOUNT in the painted part of the skirt, and also ground it up pretty well. Also cracked up the GP sill plate.

I’m gonna see if I can get replacements; I DO own a GP, after all. If not, I’ll fabricate replacement mounts and epoxy them in, and fix the other problems.

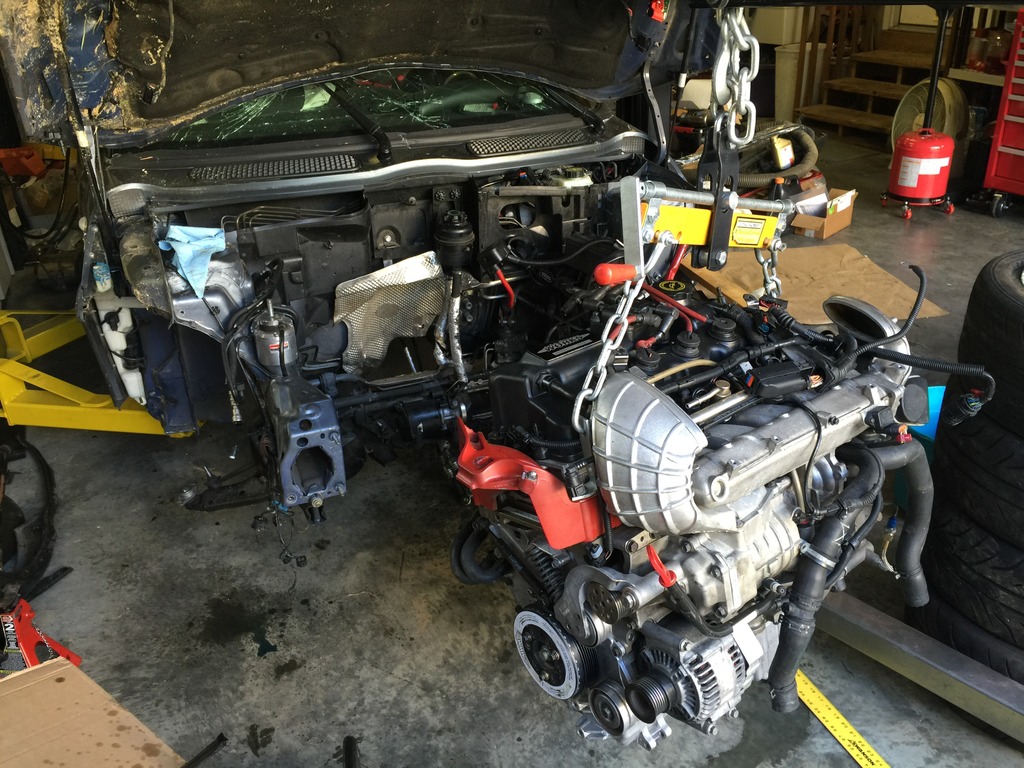

Then time to get started on the motor…

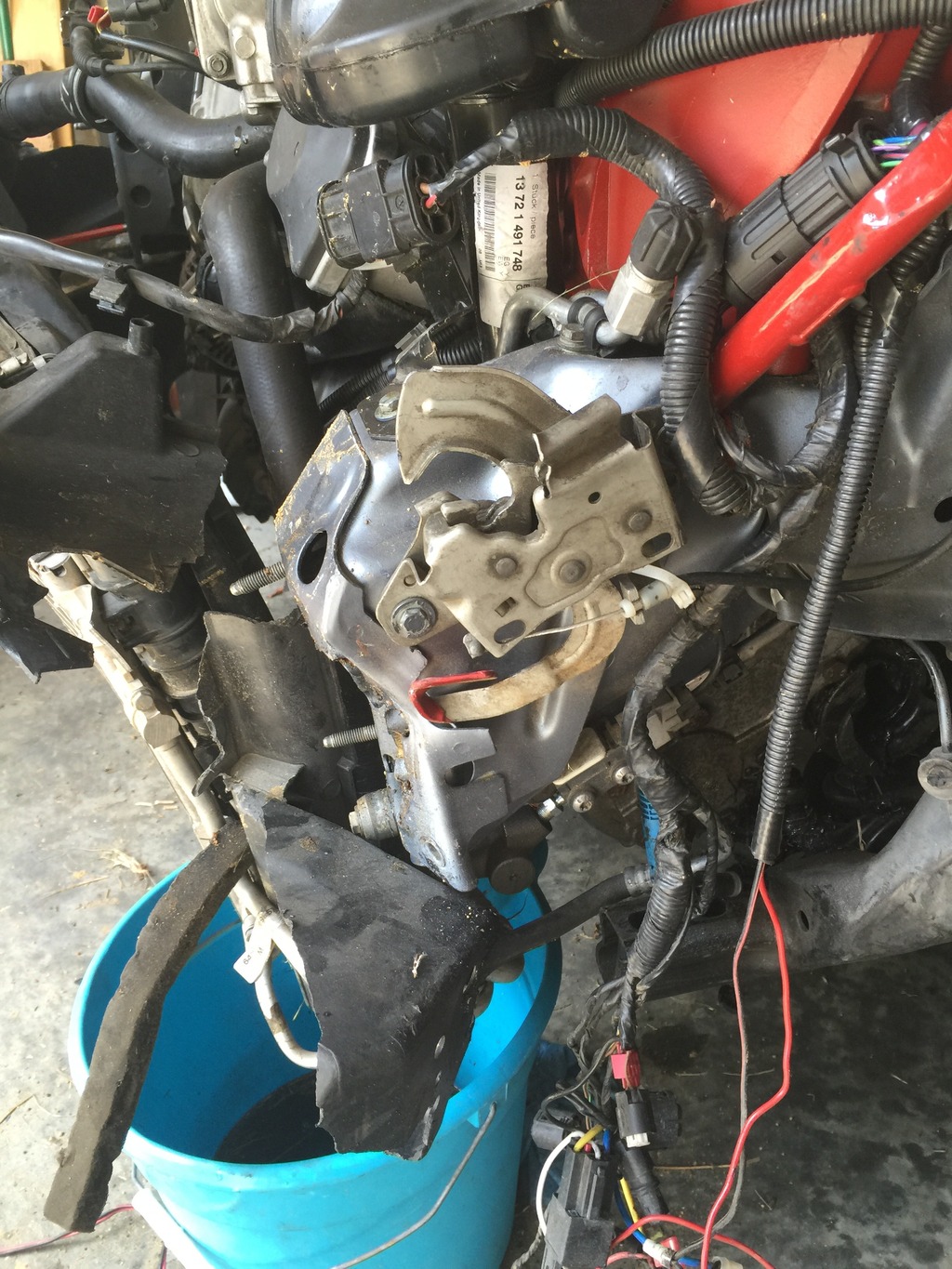

Took about an hour to get the remains of the front bumper off. The left crush tube was CRUSHED, and bent with the bumper frame in such a way that the only hope (without cutting) was to get the tube and frame off together. That worked.

First, I had to fight for awhile to get the M7 air diverter plate off. The bolt holding it was also quite twisted. Sadly, the nice CF plate is history.

I’m not sure if I can use one anyway with the RMW dual pass radiator I’ll be installing. If I decide to use the plate, I’ll get a new fiberglass one and paint it to match the GP bumper.

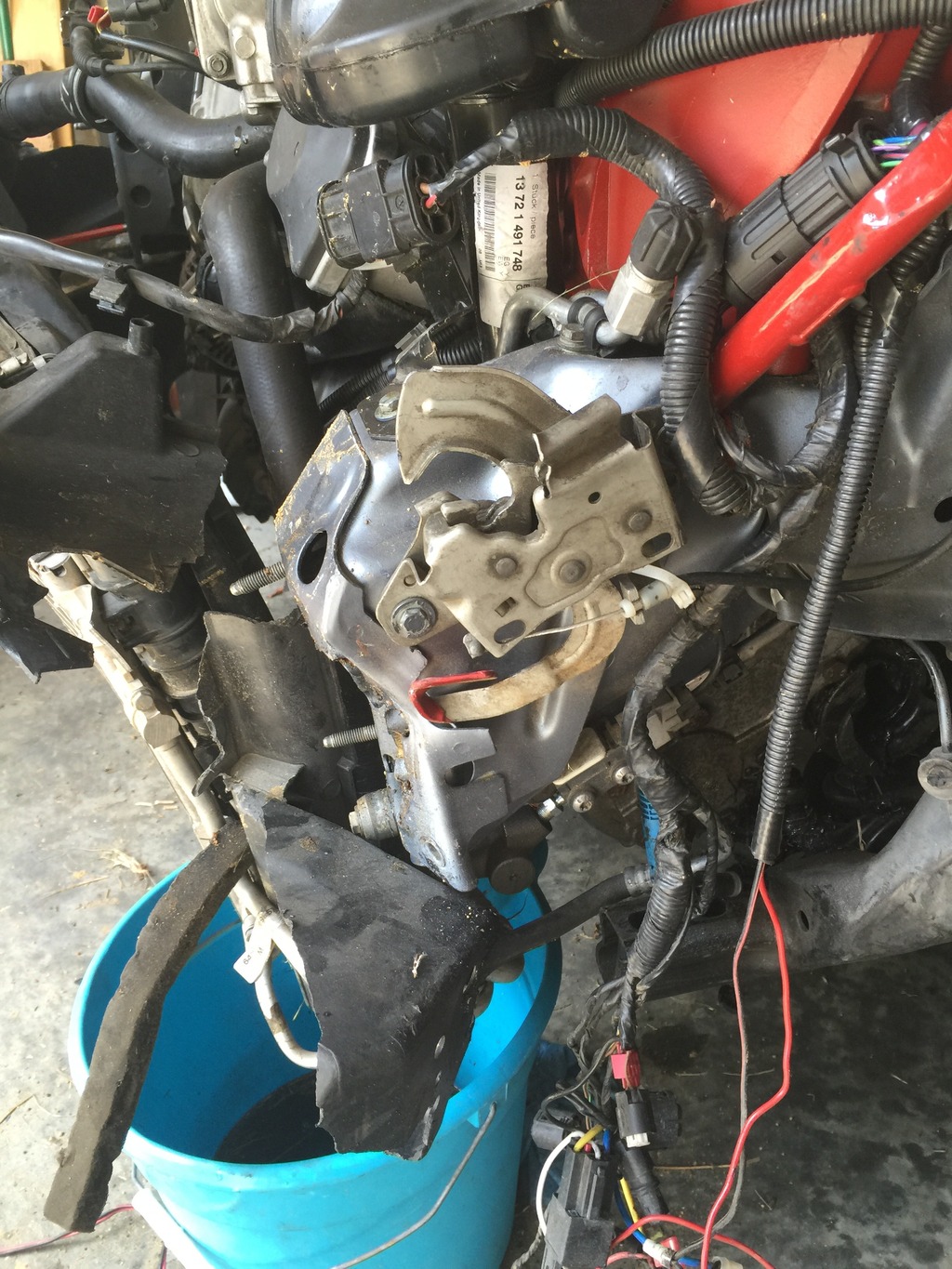

Took a minute to appreciate the carnage that is my left front suspension, wheel and tire…

And the left front frame arm…

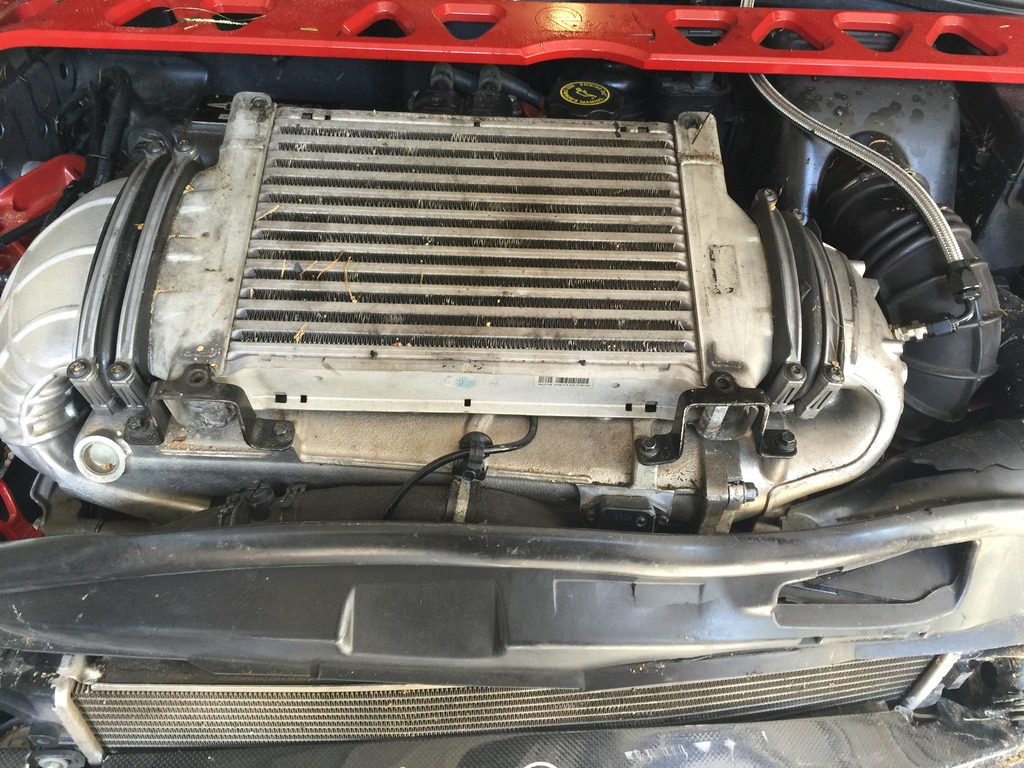

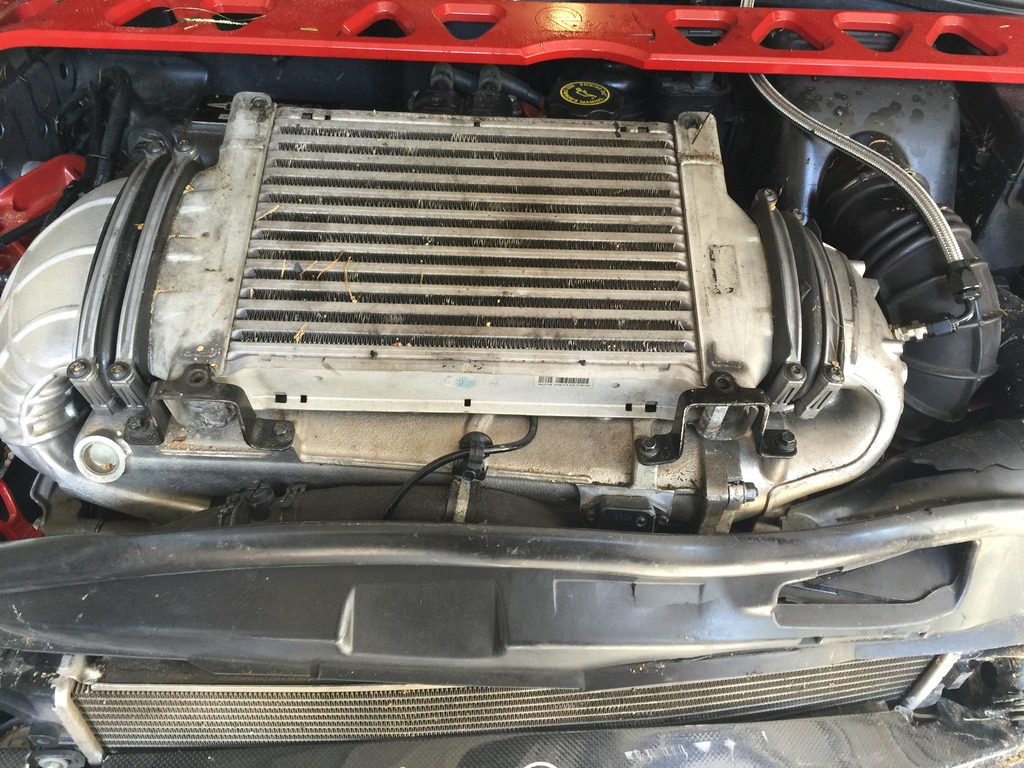

My custom red stainless intercooler diverter plate was mangled, and the corner of the ultra-expensive GP intercooler cover was busted, but it’s fixable and usable, I think. Soon I plan to have the RMW FMIC anyway.

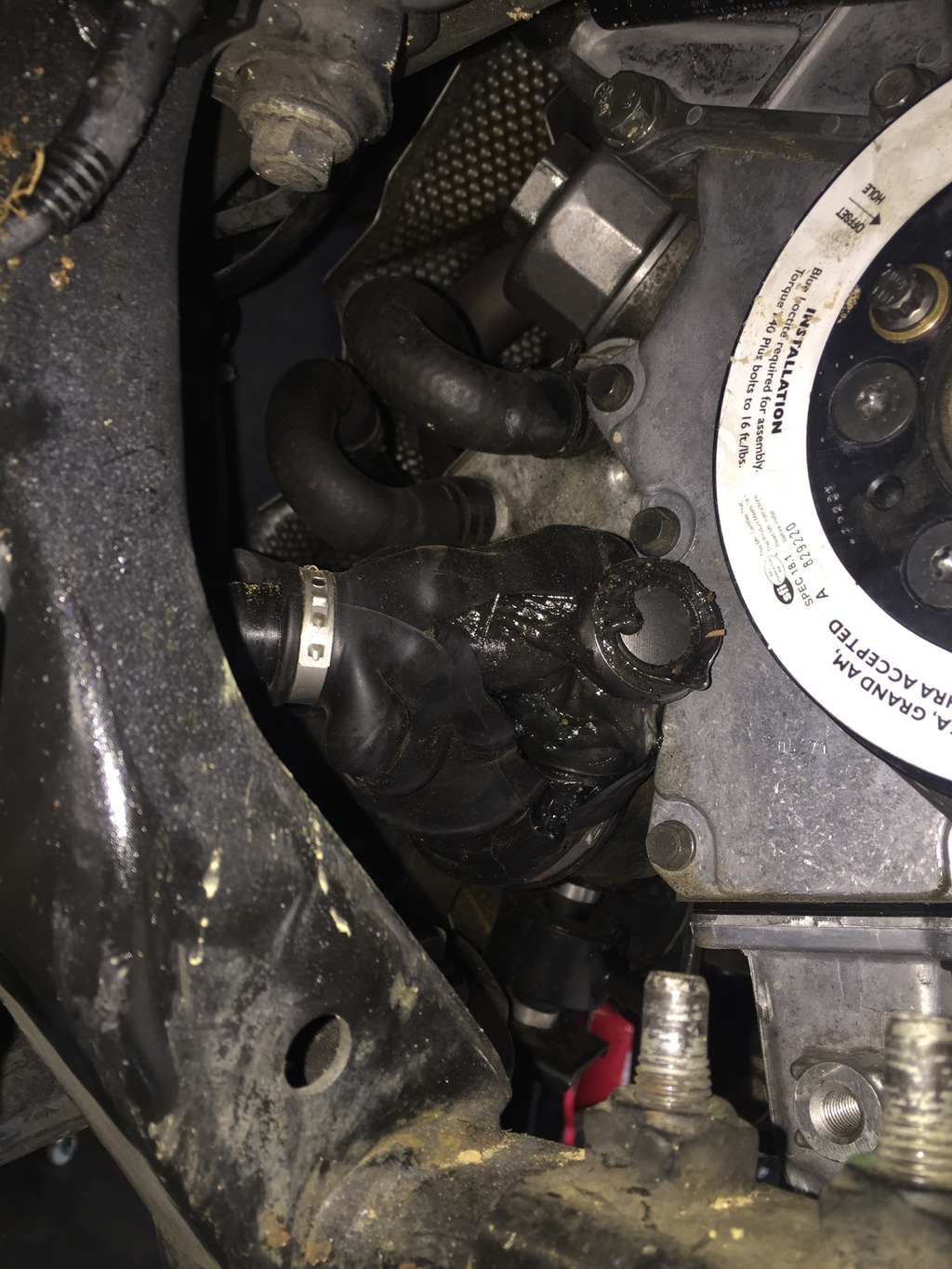

Once I got the covers off, I saw this. What’s wrong with this picture?

Uh, the intercooler really shouldn’t sit at an angle like that…

Right intercooler mount bent, and intercooler pushed back a bit, but otherwise OK. But the horn between the IC and the intake manifold is broken.

Oh well, I have a spare. And that will go away with the RMW front mount and custom manifold, anyway.

Also, my TMAP sensor was squished. That’s probably one reason it was “chugging” when I ran it for a few seconds last week. I have an old spare TMAP in a box… put it on.

Pulled off my strut bar. It seems fine.

But the strut towers… not so much.

And looks like this Vorschlag plate may have some issues also. Won’t know for sure until I get it out.

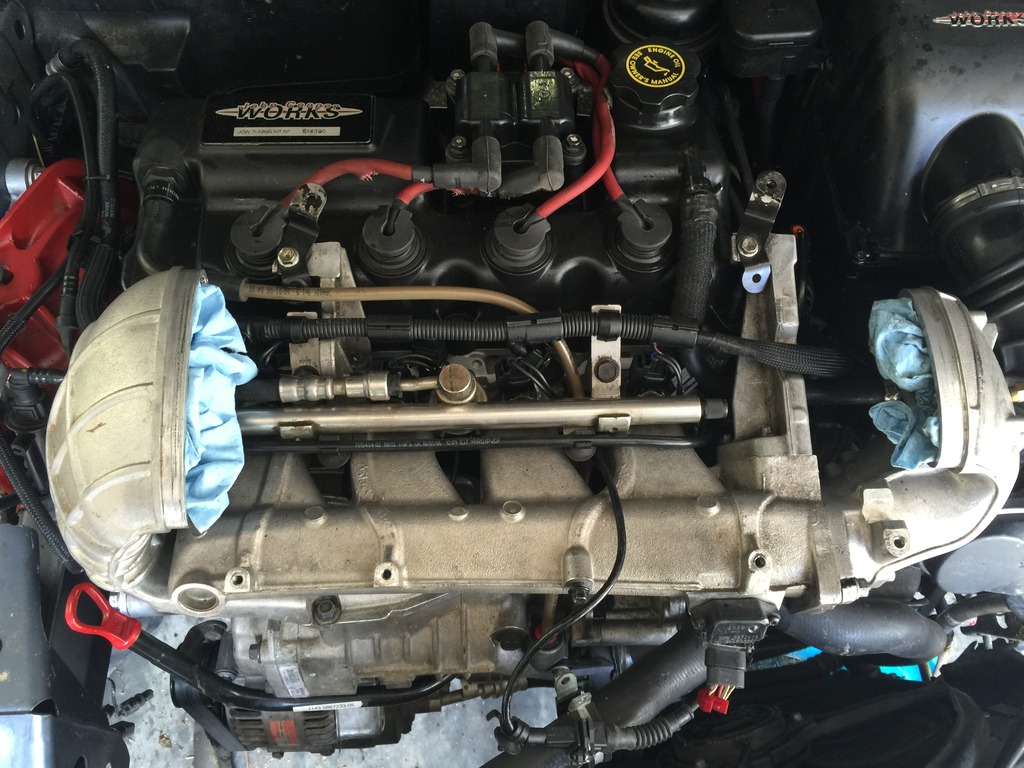

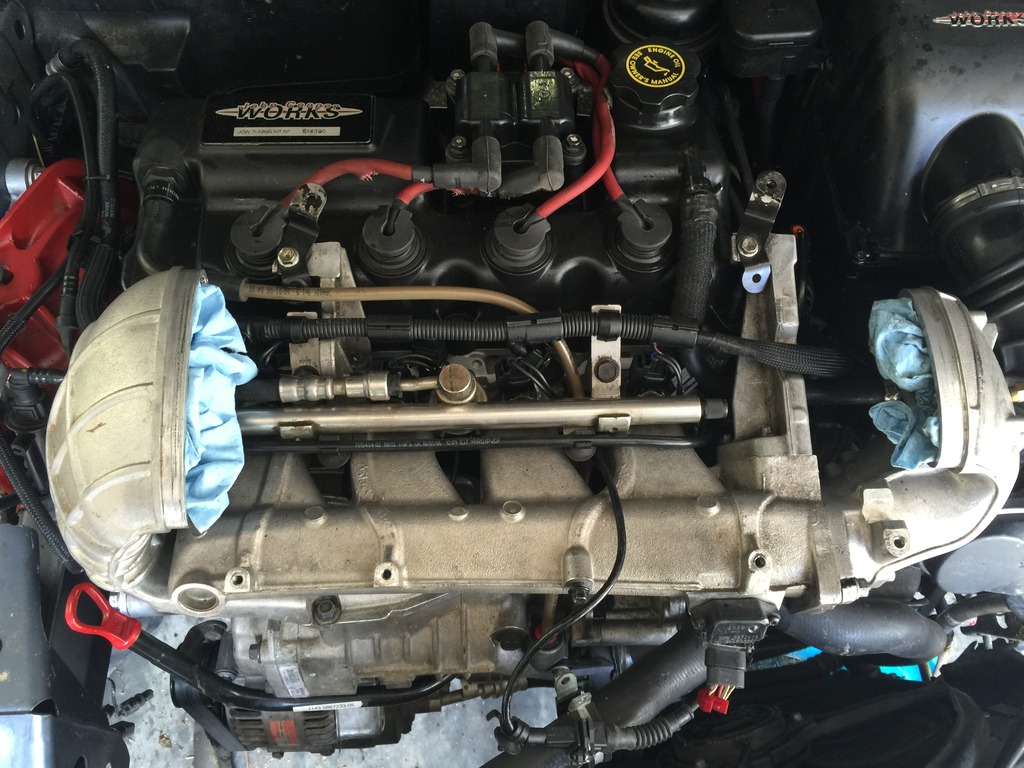

Ready to pull the coil, wires and plugs for testing.

Plugs were super fouled with oil (shocker… the car was upside down for an hour or two).

Once the plugs were out, I pulled the fuel pump fuse and did compression testing. Results:

1: 190 psi

2: 190 psi

3: 190 psi

4: 200 psi

That looks good.

Then did leak down tests, at 80psi. All cylinders held at 75-78psi, cold (you’re really supposed to warm up the engine first). That’s only 5-6% leak down, which is quite good for a cold engine. The oily cylinders & rings probably helped that a bit.

Since compression and leak down seemed OK, decided to top up the cooling system with water, replace the crushed TMAP sensor, and try to run it…

It’s amazing how well the motor runs, considering how broken the rest of the car is, and what it’s been through.

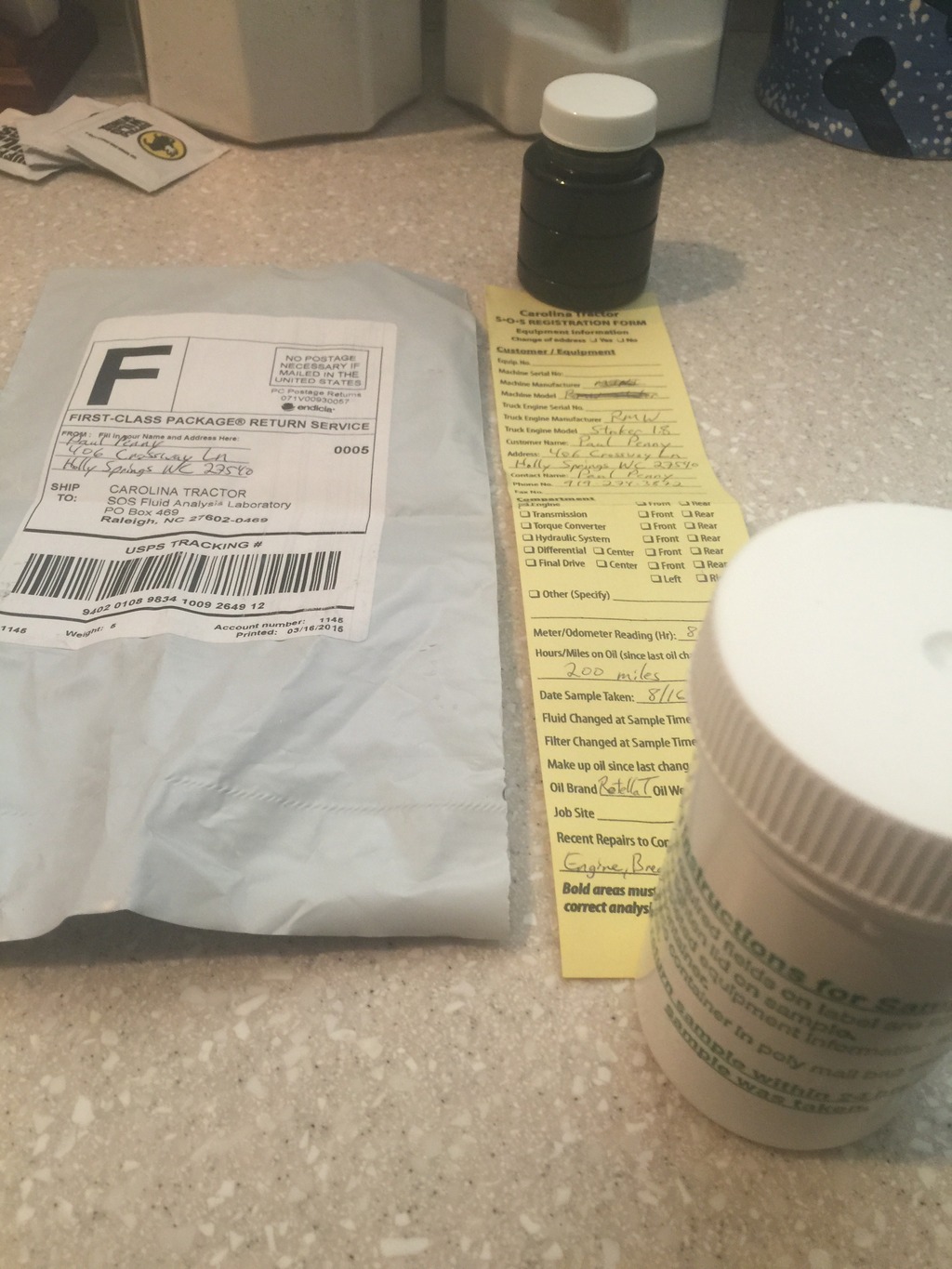

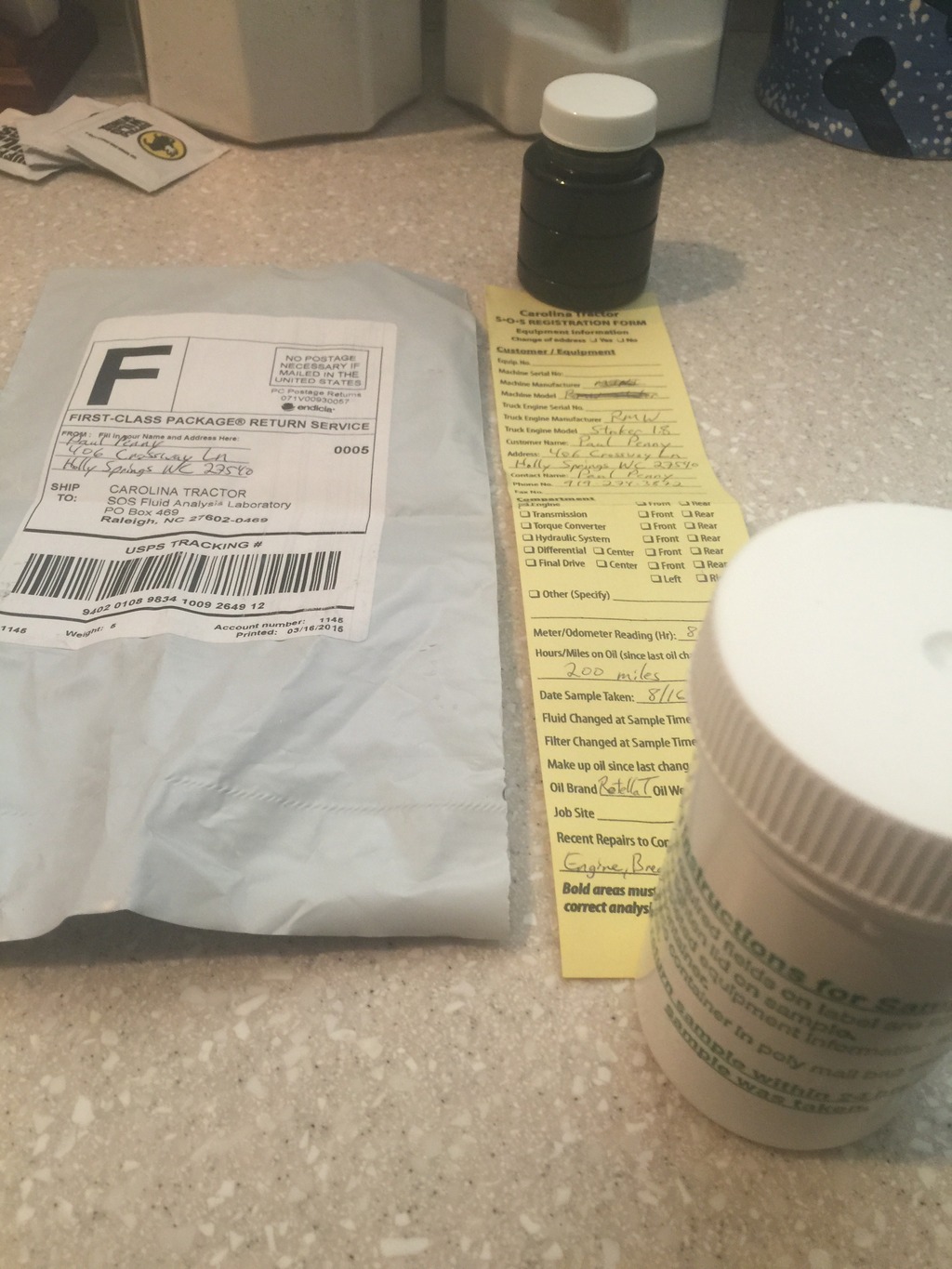

I pulled an oil sample for analysis. If it shows high lead, that’s an indicator that I may have bearing damage. If it doesn’t… I’m probably good to go with the motor as-is.

A friend sent me this oil analysis kit, he had extras. He gets them from the local Caterpillar equipment dealer… only $15 per test. I’ve used Blackstone and BobIsTheOilGuy previously… but will be using this service from now on, the price is RIGHT. Comes with a great little pump for filling the sample bottle from the dipstick tube.

And the oil lab they use is right here in town… so I expect to have results this week. Then can make a go/no-go decision on whether I’ll run the engine as-is, or send back to RMW for rework.