Back to business.

As my intrepid readers may recall, I had beautiful Pure Silver base+clear paint on the cage. Alas, such beautiful things do not last.

I’m pretty sure the VHT self-etching primer, didn’t. Followed all the directions, and it was great for a little while, but eventually the paint came off in sheets.

So, time to pull the interior out AGAIN, and strip and repaint the cage.

Time to get out my trusty 90 degree die grinder, with 4″ brass brush.

As luck would have it, only about half the paint was loose. The other half was pretty well adhered. But it all needed to come off… That took probably 6 hours spread over a week and a half. It SUCKED.

But, finally, was done.

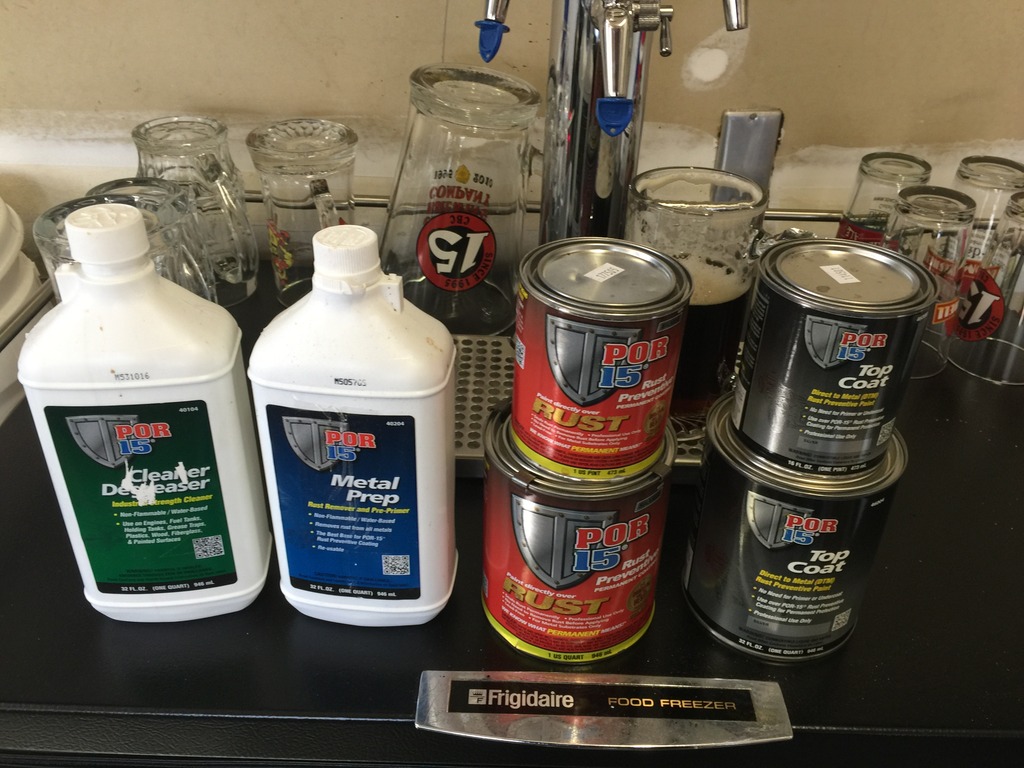

Then time to prep and paint. This time, I decided to try the POR (Paint Over Rust) system.

All this is serious stuff. Use gloves, goggles and respirator for the cleaner/degreaser and the metal prep. Put down good heavy plastic drop cloths to catch the excess stuff. Remove anything you’re worried about getting it on, first. Sprayed on the degreaser (diluted about 2 parts water / 1 part solvent), then scrubbed and rinsed with water and wiped down with wet shop towels until towels came off clean.

Let it air dry, then used the Metal Prep. This stuff is phosphoric acid and zinc phosphate. It etches the steel, and leaves behind a zinc phosphate coating. You spray on the metal prep full strength, and need to keep the steel wet with it for 20-30 minutes. For something like a roll cage, that means you’re pretty much spraying it continuously; by the time you get the whole thing sprayed, you need to go back and start over again, to keep it wet. Then rinse with water (also from a spray bottle, in my case) and let it dry. When it dries, it leaves behind a dull gray zinc coating, almost looks galvanized. This step is critical; the POR will not adhere well to clean, unrusted steel unless it’s properly prepped.

Let it dry overnight (until “bone dry” per the instructions) then apply the POR-15. This stuff is pretty awesome. The silver color is a nice bright metallic silver, and dries to a high gloss, almost looks like it has a clear coat on it, but doesn’t. When fully cured, it is VERY hard, almost like powder coat, but maybe harder. Unfortunately, it’s UV sensitive, and will dull if exposed to sunlight. So for anything that’s going to get much sun, you need to cover the POR-15 with the POR Top Coat, which is less pretty.

When applying the POR-15, follow some rules:

- Always wear disposable gloves

- Never wear nice clothing, watches, eyeglasses, or anything else you don’t want to get the stuff on, because it will NEVER come off, once dry.

- Never get it on anything you don’t want it on. If you do, remove it immediately while wet, using a solvent to clean up. Because, once dry, it will NEVER COME OFF.

Stirred the POR-15 well, then brushed it on using a cheap synthetic bristle brush. Don’t bother trying to clean the brush. Just use ones you can throw away, and start each coat with a fresh brush. Applied two coats, about 2 hours apart. The stuff flows out very nicely, but it also tends to run and sag if you don’t use very thin coats. I put it on a bit heavy, and have some sags, but don’t really care. It’s a roll cage, and most of it will be covered with pads, harnesses, etc.

After about 4 hours, the second coat was dry to the touch, and pretty hard. Then applied first coat of Top Coat, waited about an hour, and applied a second coat. The Top Coat has more of a satin silver finish, which I like. Again, used a fresh bristle brush for each coat. With both paints, pour about 4-8 oz in a cup and use that to paint, don’t paint from the can, and don’t put unused paint back in the can. You need to clean the rim of the can thoroughly before putting the lid back on, or it will be cemented in place when dry.

I’ll let it cure for a few days, then will refit the interior. Hopefully for the last time for a while.