OK, my groovy babies. It has BEGUN.

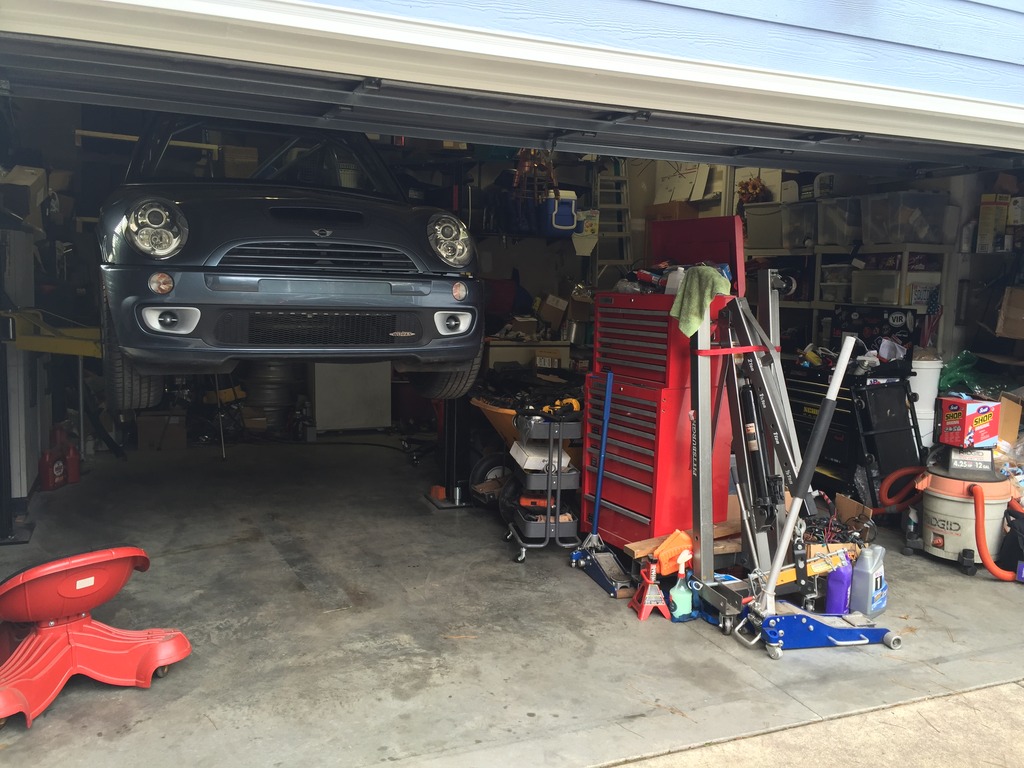

Worked on it 7 hours today. My strategy is to (a) try to do things in a planned order, so I can minimize rework and (b) try to shrink the pile of parts as quickly as practical, to make space to work in the garage and (c) do some pretty stuff first, because I’ll be more motivated to do grunge work (like the wiring harness) on a car that already looks pretty good.

So, today’s accomplishments include:

- vacuumed crap out of it

- Cleaned grunge and paint off windshield and windshield header

- removed rear heat shields and bumper frame

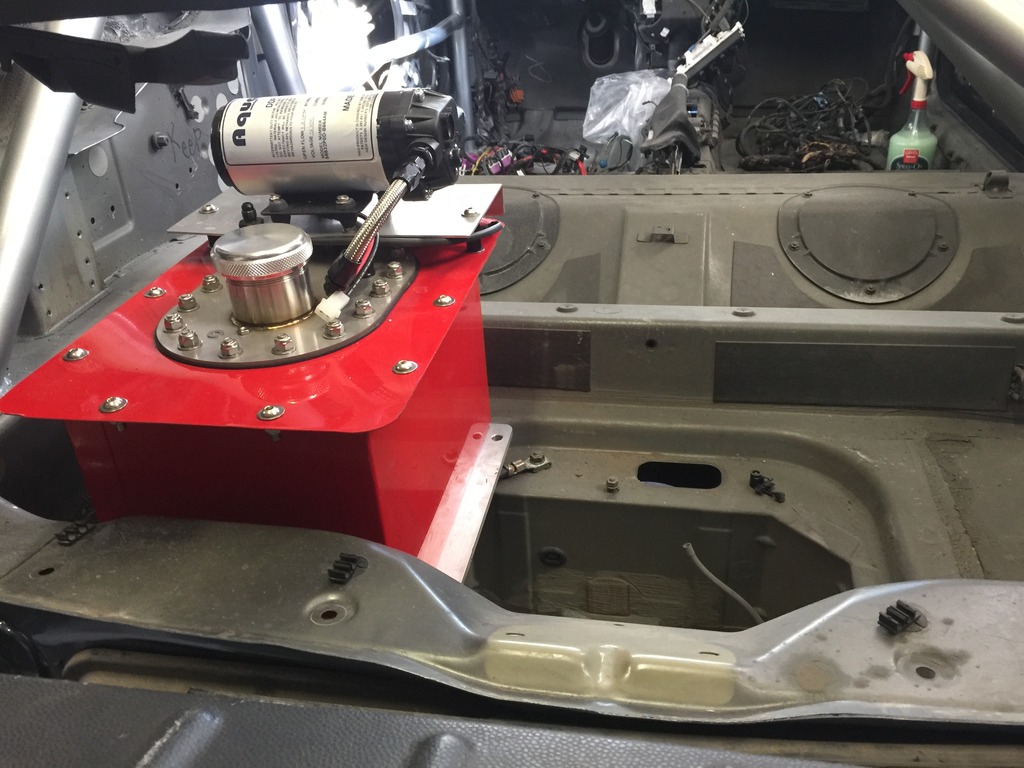

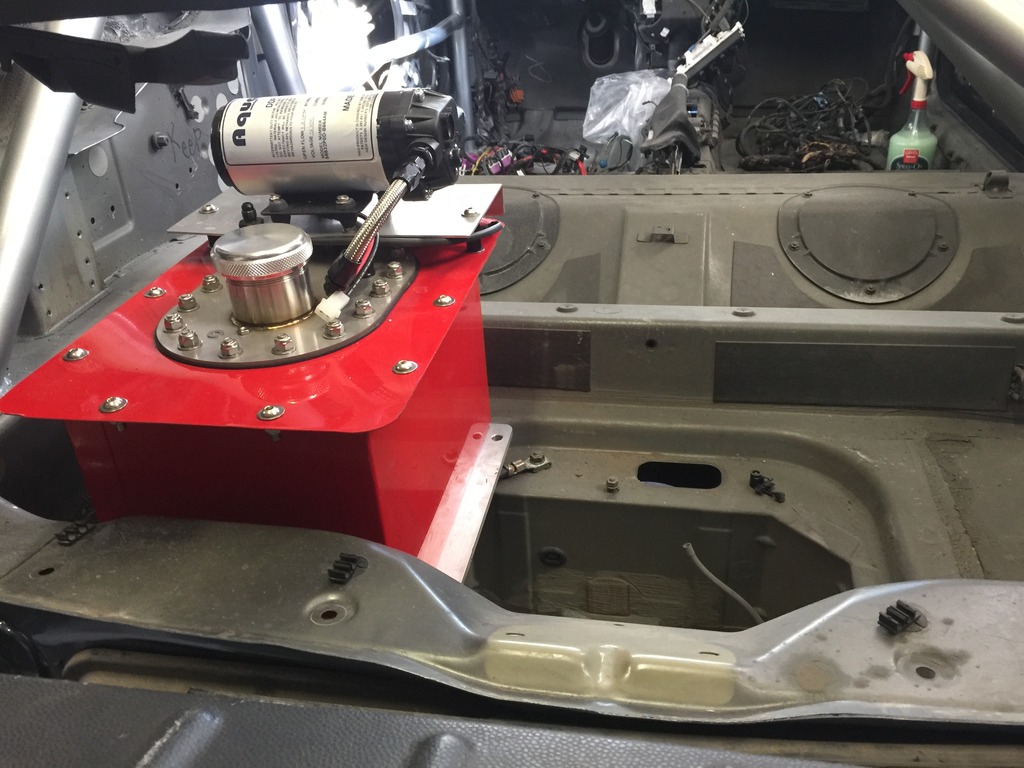

- Drilled and installed nutserts and bulkhead fittings for meth

- Installed MiniFini hitch, bumper frame and bumper cover

- Installed boot handle

- Installed GP rear trim

- Installed badges front and rear

- Installed rear hoop from convertible top and accompanying latch hardware. Determined it’s pretty bent, worked on straightening it for a while, gotta play with it some more.

- Assembled and installed hood grille and scoop.

- Put turn signals, corner lights, grille and splitter on the new bumper.

- Installed bumper frame and bumper.

- Installed new headlight rings and glued in new headlight washer covers.

- Installed headlights and tail lights and side scuttles.

- Installed A-pillar covers and most of the beltline.

Business end of meth system is installed…

Yeah, when you land a flying MINI cabrio on the left rear corner, it bends stuff. this is the rear hoop for the roof, that I’m going to use as the rear frame for my tonneau cover.

It’s gonna need some work to get back in shape. It’s a dang strong, stiff extrusion. My initial efforts to straighten it didn’t do much, I’m going to have to get creative. But it can wait a while.

Tomorrow: Wiring harness, door handles / hardware, windows, mirrors, door panels. Weather strips. Right hood latch, hood latch cables, parking brake cables, brake and clutch lines, maybe some other stuff.